NOTE: You have to remove the A/C belt to change the Alternator belt, so unless it's an emergency situation it's best to plan on replacing both of them.

NOTE: The A/C belt only operates the Air Conditioning Compressor. If the Air Conditioning is not working, you can safely leave that belt off until you get around to repairing it.

BELT TENSION: When checking or replacing the belts, check the tension by pressing on the belt with your finger at the longest span. You should be able to move the belt about 1/2 inch. Too tight is better than too loose.

NOTE when installing new belts, it is important to recheck the belt tension after a few hundred miles as new belts may stretch slightly with first use.

ALTERNATOR

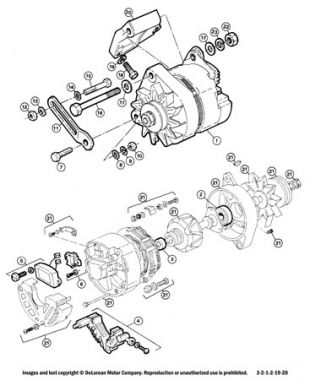

The alternator belt tension is adjusted with a sliding alternator bracket. There are very slight differences between the earlier Ducellier alternator and the later Motorola/DMC alternator mounting. Depending on the original build, the sliding portion of the bracket may be at either the engine end or the alternator end of the bracket. See links to the alternator pages below.

To tension the belt, loosen three fasteners: the nut on the engine cover end of the sliding bracket, the bolt on the alternator end of the sliding bracket, and the long bolt at the top of the alternator that actually holds it to the engine. Using a pry bar pull the alternator against the belt, tighten the bolt (nut) on the sliding part of the bracket, then the bolt (nut) on the single-hole end of the bracket, and finally the long top bolt and nut.

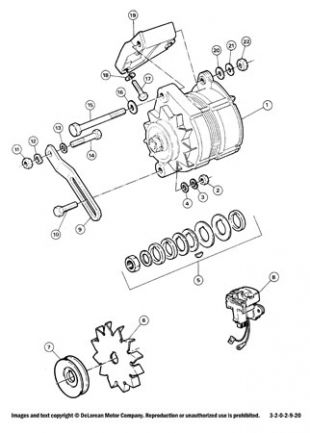

Ducellier (Early) Alternator

Ducellier (Early) Alternator Motorola (Late) or DMC Alternator

Motorola (Late) or DMC Alternator

COMPRESSOR:

The compressor belt has a separate idler system that has a slotted bracket and long bolt to adjust its tension. It is very important to note that the two bolts holding the assembly to the engine (ID #4 in the belt illustration) must be loosened slightly before you can adjust the belt. If they are not loosened you can bend the entire assembly. There is a lock nut (ID #18) on the long adjustment bolt (ID #17) that needs to be loosened before making the adjustment, and tightened when finished, or the bolt will fall out later.

The idler pulley bearings PN 105638 are prone to wear out due to their proximity to the muffler, and should be changed at the first hint of noise from them. You can easily isolate a noisy upper bearing by lifting the belt off the pulley and spinning the pulley with your fingers (ENGINE OFF). If the upper bearing is noisy change them both. When ordering the bearings be certain to order the O-Ring PN 102820 that goes behind the inner cap, or you will have oil leaks when finished.

When servicing the pulleys, take careful note (and photos) of the assembly as you take it apart. There are several unique washers and spacers which MUST be assembled in the correct order to ensure alignment of the belts and pulleys. If done incorrectly the belt can be thrown or have a very short service life. There are assembly details in the service manual HVAC section.

Edited 6/7/2016 DAS Added links, minor edits

Revised 1/13/2022 ET (formatting and links)